Measuring error

Besides the basic accuracy of the Pt100 sensor, the following additional errors may occur:

- Self-heating

- Line error

- Insulation error

- Parasitic thermoelectric voltages

Self-heating of the Pt100

To measure the resistance of a Pt100 sensor, a current must flow through the sensor. The measuring current generates a power loss and thus heat at the sensor. The associated measurement error of a higher temperature indication depends on various influencing variables:- Height of the temperature measuring resistor

A Pt1000 sensor is heated ten times more than a Pt100 resistor. - Dissipation of the generated heat

The measuring fitting should be installed in such a way that the medium flows around it optimally. The higher the flow velocity of the medium, the higher the heat dissipation.

Particularly in small volumes or gases at now flow. measuring errors can be considerable.

- Measuring current

Today, a measuring current of 1 mA is common. This means a power loss of 0.0001 Watt.

If the self-heating coefficient (E) of the measuring armature is known, the optimum measuring current at the desired max. measuring error can be calculated using the following formula.

E=t/(R * I2)

The max. measuring current for the tollerated measuring deviation then results from the formula:

I = (t/E -R)2

E= Self-heating coefficient

t= (displayed temperature) - (temperature of the medium)

R= Resistance of the temperature sensor

I= Measuring current

- Heat capacity and heat conduction of the measuring armature

When installing the Pt100 measuring resistor, optimum temperature transition must be ensured (e.g.: thermal paste, suitable insulation material). The material of the installation fitting should have the highest possible thermal conductivity (e.g. metals).

--> Top

Line error Pt100

The line error results from the connection of the Pt100 resistor to the evaluation electronics with a 2-wire connection line (two-wire connection). The resistance of the connecting cable is included in the measurement as an error.Particularly with long connection lines and small line diameters, this can lead to considerable measuring errors. With modern evaluation devices, the resistance of the connecting cable can be compensated, but temperature fluctuations on the cable cannot be taken into account. The resistances of the Pt100 and the connecting cable add up, resulting in the display of a higher temperature.

This can be remedied by connecting the Pt100 in 3- or 4-wire technology.

--> Top

Insulation error Pt100

Penetration of moisture into the sensor or into the insulating material between the connecting cables, leads to a measuring error (lower temperature). temperature).The sensors are normally sufficiently protected against moisture. However, when manufacturing the measuring insert, care must be taken to use absolutely dry insulating materials and careful sealing.

--> Top

Parasitic thermoelectric voltages Pt100

When different metals are joined, a thermoelectric voltage occurs.Such metal connections occur, for example, when extending the sensor connection wires with copper wires. Normally, the connection points have the same temperature and thus cancel each other out in terms of value. However, if different temperatures are present at the connection points, e.g. due to different heat dissipation, different thermoelectric voltages occur which lead to a voltage drop which is interpreted by the evaluation device as a change in resistance.

This results in a measurement error.

How high the measuring error is strongly depends on the evaluation device and the selected connection type (2, 3 or 4-wire). Fault detection by reversing the measuring current. The higher the difference of the measured values, the higher the thermoelectric voltage present.

--> Top

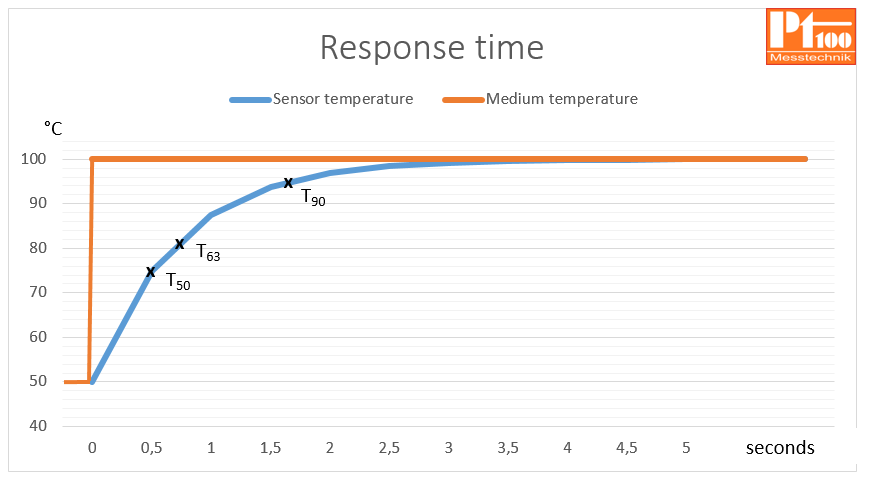

Response time Pt100 (T50, T63, T90)

In many applications, the speed with which a temperature sensor reacts to a change in temperature is crucial for precise control and regulation of the process.As a temperature sensor only reacts with a delay, especially in the event of sudden temperature changes in the medium, this can lead to undesirable process errors or even damage to machines or systems.

How quickly a Pt100 temperature sensor reacts to a change in temperature depends on various factors.

- Design of the temperature sensor

The Pt100 sensor must have the best possible contact with the surrounding protective fitting (e.g. with heat-conducting paste). The smaller the mass of the sensor and the protective fitting, the faster the temperature sensor reacts to temperature changes. Temperature sensors defined as fast responding, often have have a tapered measuring tip. - Measuring medium

Depending on the medium to be measured, the heat transfer from the measuring medium to the temperature sensor varies. As gases are poor heat conductors, heat transfer is slower with gases than with liquids. The flow rate also plays a role in the heat transfer from the medium to the Pt100 temperature sensor. The faster the medium flows, the faster the heat transfer. - Installation of the temperature sensor

For optimum heat transfer between the medium and the temperature sensor and to avoid heat dissipation, the resistance thermometer should be immersed as deeply as possible in the medium. It must also be ensured that the medium flows optimally around the sensor and that it is not surrounded by stagnant medium (dead water zones).

This specifies the time a temperature sensor needs to go from a certain initial temperature to 50% (T50), 63% (T63) or 90% (T90) of the temperature difference between the initial and final temperature.

For example:

Rapid increase in medium temperature from 50 °C to 100 °C

This is a temperature jump of 50°C.

The T50 value is therefore the time (in seconds) until 75 °C = 25 °C (50% of the temperature jump) + 50 °C (initial temperature) is reached.

Accordingly:

T63 Time required for the temperature sensor to reach 81.5 °C

T90 Time required for the temperature sensor to reach 95 °C

The response time of a Pt100 temperature sensor is determined by the manufacturer and specified in

the data sheet.

Correctly, the temperature range in which the measurement was made should also be specified.

Example: T50: 0,5 seconds from 50 to 100 °C

T0,5 is also often used instead of T50, T0,63, instead of T63 or T0,9 instead of T90.